Discover Our Products

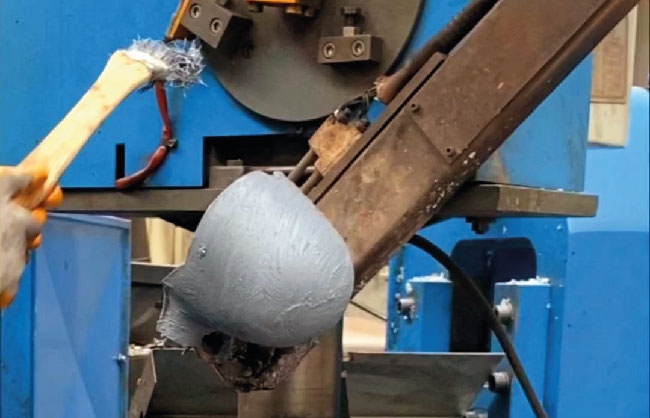

Consumables

Here you can find all the materials your company may need for casting processes. We offer a wide range to provide our customers with the highest quality products:

- All Alloy Metals

- Melting and Holding Crucibles

- Fluxes

- Sleeve and Piston Technologies

- Die Casting Mold Release Agents

- Liquid Piston Lubricants

- Granular Piston Lubricants

- Auxiliary Equipment

Phone

+90 (552) 356 3330

Address

Tatlıcak Mh. Kaside Sk. No:5A Karatay, KONYA TR